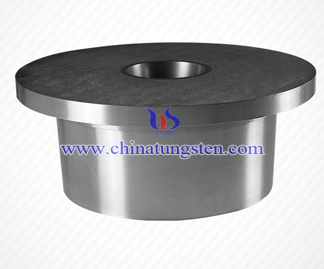

Tungsten Carbide Seat Sealing Form

The main function of the valve is opening or closing the fluid passage conduit. The tungsten carbide seat is one of the most important valve components, when the ball valve is closed, it serves to prevent the media flows from the upstream chamber, from the chamber downstream of the flow effect. Tungsten carbide seat has good polishing, low energy consumption, wear resistance, high temperature resistance, corrosion resistance, and recyclable and other excellent features, it is widely used in oil drilling, pumping, thermal recovery wells, sand well, the coal fields.

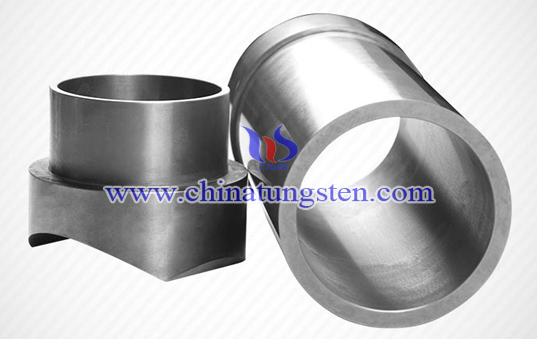

Seal in the form of a lot of seats, seating commonly divided into fixed seat floating ball valve and fixed ball floating seat two categories. Fixed seat floating ball valve, a sphere produced under fluid pressure in the fluid flow direction of displacement, and to make it more closely contact with the back seat sealing, forming one-sided sealing. Fixed ball floating seat, is the fluid pressure can not make the ball displacement, but the seat by a spring or fluid to push the ball beat the establishment than the pressure seal. Can form a double-sided seal. Fixed ball floating seat double separable double truncated and emissions (DBB), double isolation and emissions (D1B) and other structures.

With the development of the energy status quo competition and long-distance pipeline industry, crude oil pipeline technology, and increase the amount of crude oil for heavy oil development to the deep sea, as a commitment to the important task of the long-distance pipeline valve, its internal work environment will become more severe, requiring tungsten carbide seat has higher wear, corrosion and erosion resistance.